Showroom

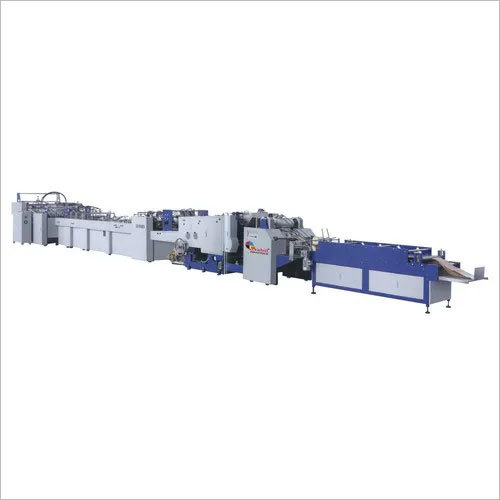

Fully Automatic Non Woven Bag Making Machines are the machines of boosted

production efficiency which can be operated at high speed. The machines allow

for advanced mass production and are suited for large-scale manufacturing

processes.

The

Non Woven Bag Printing Machines are designed to make prints on non-woven bags in

an efficient and quick way. These are accessible with high production volumes

and ensure cost savings as well as boosted profitability for businesses.

The Paper bag making machines we deal in are used to make bags in

several designs, shapes and sizes, as per assorted industrial specific

requirements. The machines allow for advanced utility and help in boosting the

brand visibility.

The Automatic

Soft Handle Sealing Machines are the specific equipment, widely demanded in the packaging

industry to make soft loop handle bags. The machines are also used to seal the

retail and grocery stores.

The Non

Woven Fabric Making Plants we deal in are suited for a wide range of

applications across several industries. Supplied plants are suited for the

production of many disposable medical products, filtration systems, hygiene

products, automotive interiors, geotextiles, and others, used in many segments.

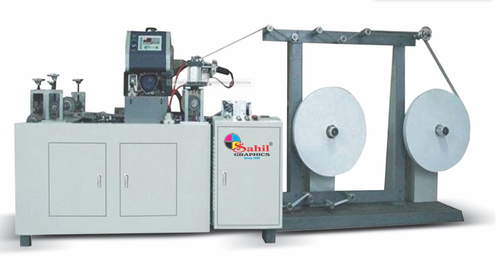

The Offset

Machine with Online Numbering & Perforation is popular as a highly particular printing press suited for

several commercial printing applications. The machines is accessible with an

offset printing as well as exclusive method enabling high-quality prints, with

advanced perforation features.

Call Me Free

Call Me Free